Introduction:

Injection mould design plays a pivotal role in the automotive manufacturing process, shaping the very foundation of vehicle components. From intricate interior parts to robust exterior elements, the efficiency and precision of injection mould design significantly impact the quality, performance, and overall success of automotive production. In this article, we delve into the critical importance of injection mould design within the realm of automotive manufacturing, exploring its influence on both plastic injection molding manufacturer and the automotive industry at large.

Understanding the Significance:

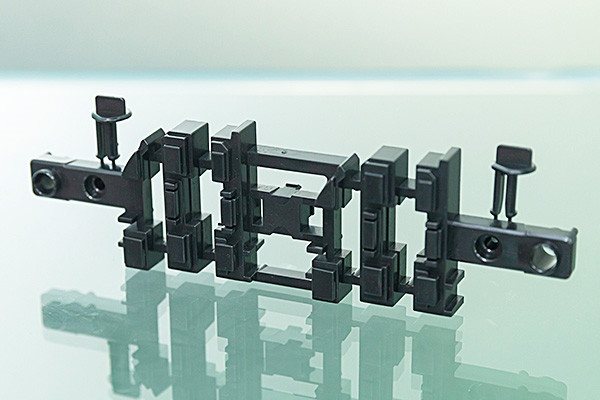

At the heart of automotive plastic injection molding lies the intricate process of injection mould design. Manufacturers in this field must meticulously craft moulds that not only meet the stringent standards of the automotive industry but also optimize efficiency, durability, and cost-effectiveness. A well-designed injection mould forms the cornerstone of successful automotive manufacturing, influencing factors such as part quality, production speed, and overall profitability.

Meeting Industry Demands:

As automotive design trends evolve and consumer expectations continue to rise, the pressure on plastic injection molding manufacturers to deliver innovative solutions has never been greater. Injection mould design must adapt to accommodate advancements in materials, technologies, and sustainability practices while ensuring compliance with stringent safety and performance standards set forth by the automotive sector.

Enhancing Performance and Efficiency:

Efficient injection mould design directly translates to enhanced performance and efficiency in automotive manufacturing. By optimizing factors such as cooling channels, gate placement, and part geometry, manufacturers can minimize cycle times, reduce material waste, and maximize production output. This not only improves the overall cost-effectiveness of the manufacturing process but also enhances the competitiveness of automotive products in the market.

Driving Innovation and Differentiation:

In today’s highly competitive automotive landscape, innovation is key to staying ahead of the curve. Injection mould design serves as a catalyst for innovation, enabling manufacturers to explore novel designs, materials, and production techniques. From lightweighting initiatives to the integration of smart technologies, innovative mould design empowers automotive manufacturers to differentiate their products, meet evolving consumer demands, and drive industry progress.

Collaboration and Expertise:

Successful injection mould design for automotive applications requires a collaborative approach between plastic injection molding manufacturers, automotive OEMs, and design engineers. By leveraging collective expertise and industry insights, stakeholders can co-create mould solutions that not only meet technical specifications but also align with broader strategic objectives such as sustainability, scalability, and supply chain resilience.

Furthermore, the role of injection mould design extends beyond the initial production phase to encompass the entire lifecycle of automotive components. Well-designed moulds contribute to the longevity and reliability of vehicle parts, ensuring consistent performance and durability over time. Moreover, as automotive manufacturers increasingly focus on circular economy principles and end-of-life considerations, injection mould design plays a critical role in facilitating component recyclability and material reusability.

By prioritizing sustainability and lifecycle considerations in mould design, plastic injection molding manufacturers can support the automotive industry’s transition towards more environmentally responsible practices, thereby contributing to a more sustainable future for mobility.for more vist :https://www.djmolding.com/

Conclusion:

injection mould design stands as a cornerstone of automotive manufacturing, influencing the quality, efficiency, and innovation of vehicle production. As plastic injection molding manufacturers continue to navigate evolving industry dynamics and technological advancements, the role of injection mould design remains paramount in driving progress and shaping the future of automotive manufacturing. By prioritizing excellence in mould design, stakeholders can unlock new opportunities for advancement, differentiation, and sustainable growth in the automotive sector.