As dental technology continues to advance, the options for implant restorations have grown exponentially. For dentists and oral surgeons, selecting the right components is crucial for the success of dental implants. In this comprehensive guide, we will delve into how to choose the right casting abutments with conical connections, ensuring optimal outcomes for your patients.

Understanding Casting Abutments and Conical Connections

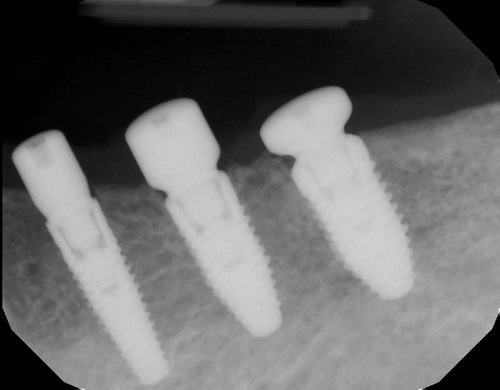

Before we dive into the selection process, it’s important to understand what casting abutments and conical connections are. Casting abutments are customizable components that serve as a connector between the implant fixture and the final prosthesis. They can be either prefabricated or custom-made depending on the patient’s needs.

On the other hand, conical connections refer to the design of the abutment and implant fixture interface. This type of connection has a conical shape, providing better stability and sealing compared to other types of connections.

Advantages of Conical Connections

- Improved Fit and Stability: The tapered design ensures a snug fit, minimizing micromovements that can lead to implant failure.

- Enhanced Osseointegration: The conical connection promotes better osseointegration, enhancing the stability and longevity of the implant.

- Reduced Risk of Microleakage: The tight seal formed by the conical connection reduces the risk of bacterial infiltration and microleakage.

- Increased Longevity: The robust connection contributes to the overall durability and success rate of the implant restoration.

- Customization: Conical connections offer more flexibility for customized restorations, accommodating various clinical scenarios.

Factors to Consider When Choosing Casting Abutments with Conical Connections

When selecting casting abutments with conical connections, several factors need to be taken into account:

Implant System Compatibility

Not all abutments are compatible with every implant system. Ensure that the casting abutment you choose is designed to work seamlessly with your preferred implant system.

Material Options

Casting abutments are typically available in materials such as titanium and zirconia. Titanium is known for its strength and biocompatibility, while zirconia offers superior aesthetics and is often used in anterior restorations.

Emergence Profile

The emergence profile of an abutment can be straight or angulated. The choice depends on the clinical situation and the desired esthetic outcome. Angulated abutments are often used to correct implant angulation issues.

Implant Angulation

Consider the angulation of the implant when selecting an abutment. In some cases, angulated abutments are necessary to achieve proper alignment and esthetic results.

Prosthetic Requirements

Different prosthetic restorations have specific requirements. Ensure that the abutment you choose meets the needs of the final restoration, whether it’s a single crown, a bridge, or a full-arch prosthesis.

Aesthetics

For anterior restorations, esthetics play a significant role. Choose abutments that offer the best esthetic outcomes, such as zirconia abutments, which can be shaded to blend seamlessly with natural teeth.

For more information on casting abutments with conical connections, visit gdt-implants.com and explore our range of high-quality products designed to meet the needs of contemporary dental practices.

Advantages of Using Casting Abutments with Conical Connections

Using casting abutments with conical connections offers several benefits:

- Improved Fit and Stability: The conical connection provides a tight, secure fit, reducing the risk of implant failure due to micro-movements.

- Enhanced Osseointegration: The design promotes better integration with the surrounding bone, increasing the long-term success of the implant.

- Reduced Risk of Microleakage: The tight seal formed by the conical connection minimizes the risk of bacterial infiltration, protecting the implant site.

- Increased Longevity: The durability of the conical connection enhances the lifespan of the implant restoration.

- Customization Options: Conical connections offer more flexibility for customized restorations, accommodating various clinical scenarios and patient needs.

Process of Selecting and Placing Casting Abutments with Conical Connections

1. Consultation with a Dentist or Prosthodontist

The process begins with a thorough consultation with your dentist or prosthodontist. During this meeting, the practitioner will assess your specific needs and determine the most suitable abutment type.

2. Impression Taking and Model Creation

Once the appropriate abutment type is selected, impressions of the patient’s mouth are taken. These impressions are used to create detailed models, which serve as the blueprint for designing the abutment.

3. Abutment Design and Fabrication

Based on the impressions and clinical data, the abutment is designed and fabricated. This step often involves digital planning tools to ensure precision and accuracy.

4. Implant Placement and Abutment Connection

The dental implant is placed into the jawbone, and after a period of healing and osseointegration, the abutment is connected to the implant. The conical connection ensures a secure and stable fit.

5. Restoration Placement and Finalization

Finally, the prosthetic restoration is placed onto the abutment. This could be a crown, bridge, or denture, depending on the patient’s specific needs.

Conclusion

Choosing the right casting abutments with conical connections is crucial for the success of dental implant restorations. By considering factors such as implant system compatibility, material options, emergence profile, implant angulation, prosthetic requirements, and esthetics, you can ensure optimal outcomes for your patients.

The advantages of using casting abutments with conical connections—improved fit and stability, enhanced osseointegration, reduced risk of microleakage, increased longevity, and customization options—make them a valuable choice for modern implantology.