The rotavap distillation, a key methodology in chemistry and pharmaceuticals, has gained new capabilities due to recent improvements making the separation of solvents and other compounds more effective than ever. The central point of this process is not just the equipment but the accessories and strategies used with it. This article presents more complicated methods to improve the efficiency of rotovap distillation, with the right tools and techniques being explained to the professionals.

Definition

It is important to understand the basics before going into the more advanced strategies of rotovap distillation. This method involves using rotary evaporation to remove solvents from the samples through evaporation. The process is carried out by turning the sample and applying a vacuum to the system, which is much more efficient in lowering the boiling points of the solvents, and thus, the distillation takes place at a faster rate and more gently than the traditional methods ECOTEST: Asbest, EPB en EPC keuringen

Selecting High-Quality Supplies

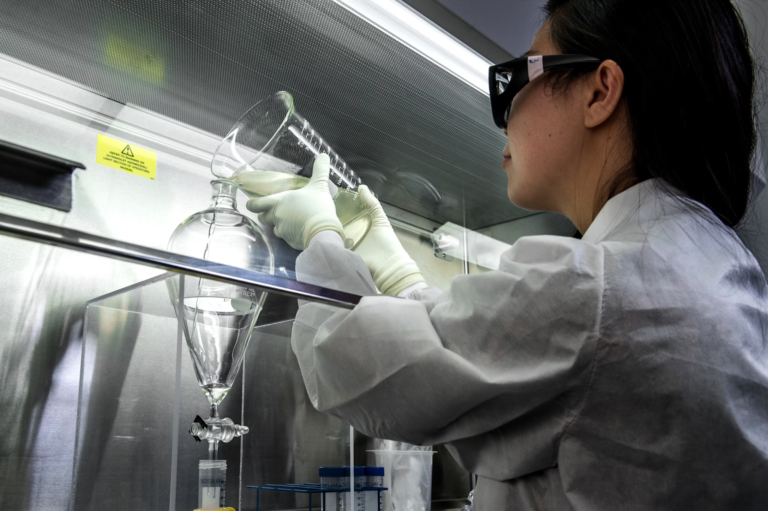

The first thing to do to improve the distillation efficiency is to ensure you are ready with first-class lab glassware supplies. High-quality glassware manufactured by trusted rotary evaporation equipment makers ensures durability and chemical resistance and is suitable for distillation processes. Investing in suitable glassware lowers the operation time and increases the lab’s safety and reproducibility.

Optimizing Vacuum Levels

The central point of the rotovap distillation process is adjusting the vacuum level to achieve maximum efficiency. The appropriate pressure of the vacuum is the key to solvent evaporation and the minimization of the boiling point. The vacuum controllers and sensors of current generations allow for the highly accurate control of the vacuum, thus enabling the distillation process to be fine-tuned.

Enhancing Efficiency

The current rotovaps have built-in functionalities that can increase the distillation efficiency. These include digital displays for real-time monitoring of temperature and pressure, programming control for repeatability and consistency, and automatic lifts for enhanced safety and convenience. By exploiting some of the sophisticated characteristics of these machines, in addition to quality lab glassware supplies, distillation becomes more precise and efficient.

Continuous Innovation

Ongoing advancement and perfecting of rotovap technology have a major impact on the higher efficiency of distillation. The rotovap distillation manufacturers with a desire to explore and develop new products are thereby consistently launching new products with improved performance, safety, and user experience.

To summarize, distillation efficiency boosting by rotovap is a strategic process that implies using quality lab supplies, the optimization of vacuum and temperature parameters, and using advanced rotovap features.

Through collaboration with leading rotary evaporation equipment manufacturers, the professional community in the field will be able to majorly upgrade their distillation processes, obtaining higher efficiency, superior results, and greater security in their laboratories.